WGGY series fully automatic oil-water separator and lifting integrated equipment

Category:Integrated Equipment

Product Details

Product Introduction

The WGGY series fully automatic oil-water separation and lifting integrated equipment is a new type of fully automatic oil-water separation and lifting equipment independently researched and developed by our company's professional technicians based on more than ten years of market experience and combined with advanced technologies at home and abroad. This equipment adopts a more economical and reasonable structural design, with a more reasonable and efficient hydraulic process and better oil-water separation effect; it adopts a more intelligent operating system, making management and maintenance more convenient. It has multiple functions such as automatic separation of large-particle debris, convenient collection of fine and soft debris, automatic separation and collection of grease, and automatic lifting and discharge of wastewater. The effluent water quality meets the environmental protection requirements of CJ343-2010 "Water Quality Standard for Wastewater Discharge into Urban Sewers".

Applicable Fields

Comprehensive discharge treatment of catering wastewater in various commercial and technological real estates; catering wastewater treatment in the canteens of enterprises and institutions; catering wastewater treatment and lifting discharge in various supermarkets, hotels and other catering places.

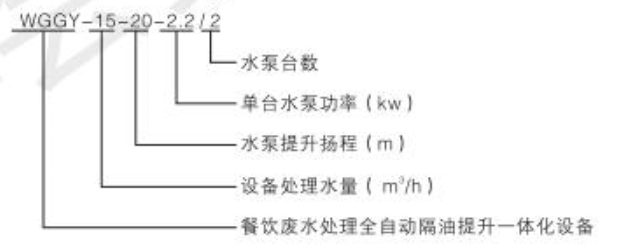

Model Description and Significance

Product Features

■The equipment cabinet and main components are all made of standard 304 stainless steel material, with good acid and alkali corrosion resistance.

■It adopts a professionally designed mechanical debris separation and collection device, which does not require manual cleaning and effectively prevents debris from entering the oil-water separation area.

■It adopts mechanical automatic oil discharge technology, effectively solving the problem of difficult discharge of grease coagulation.

■It adopts an all-stainless steel inspection hole, which facilitates later maintenance of the equipment and ensures the long-term stable operation of the equipment.

■The fully automatic wastewater lifting area adopts multi-point liquid level control and has forced discharge and over-high liquid level alarm functions to ensure stable operation of the equipment.

■The equipment operates in a fully sealed manner. After connecting the dedicated vent (DN50), the equipment has no odor leakage, ensuring a good operating environment.

■The equipment adopts an intelligent control system with multiple safety protection measures, stable operation, and simple operation.

■According to the needs of the site, various accessories can be optionally installed: automatic aeration device, weighing device, touch screen, external dry sewage pump, and communication device, etc.

Product Differences

| Comparison Items | Fully automatic oil-water separation and lifting integrated equipment | Fully automatic oil-water separation and lifting integrated equipment from other domestic manufacturers | Domestic oil separation and lifting products |

|---|---|---|---|

| Key Difference 1 | Independently researched and developed pressurization screw conveying debris separation device, automatic isolation, conveying, and pressing of debris and wastewater, efficiently solving the most difficult problem of debris separation and collection in catering wastewater. | Simple debris separation device, high water content, prone to overflow and blockage; or using a simple basket-type screen, difficult manual operation, prone to blockage and damage, resulting in the inability of the equipment to operate normally. | Basket-type screen separation, difficult manual operation, prone to blockage, overflow, and damage. |

| Key Difference 2 | Automatic grease collection and discharge function, using the best mechanical scraping oil technology, not afraid of grease coagulation, no manual cleaning required, no odor leakage, safe, environmentally friendly, and intelligent. | Simple grease collection and discharge setting, grease cannot be discharged once it coagulates, requiring manual cleaning. | Using solenoid valves and stirring, easy to block and cannot be discharged, requiring manual cleaning. |

| Key Difference 3 | Using a professionally developed two-stage oil-water separation process, the oil-water separation effect is good and superior to environmental emission requirements. | Single-stage processing technology, general effect. | Some products adopt a two-stage oil-water separation process, but are not suitable for Chinese food. |

Process and Technology Introduction 绍

How to ensure the effect of oil-water separation?

The "WGGY series fully automatic oil-water separation and lifting integrated equipment" adopts an independently researched and developed innovative two-stage oil-water separation process, efficiently removing 3-7% of solid debris, about 3% of floating oil, dispersed oil, and emulsified oil, and about 0.T70 of detergent in catering wastewater. The oil content in the effluent is less than 30mg/L, which is more than 3 times higher than the national standard.

Where does the water enter and exit? Is it easy to install?

The "WGGY series fully automatic oil-water separation and lifting integrated equipment" has an integrated structure design and is equipped with a freely pluggable dedicated base, which facilitates the transportation of the equipment on site. During on-site installation, only the inlet (national standard 1.0Mpa flange interface), outlet (national standard 1.0Mpa flange interface), and vent (national standard DN50 straight pipe) of the equipment need to be simply connected, and it can be powered on for stable operation. The installation is very convenient!

How to control the generation and spread of odor?

The root cause of the stench in catering oil-water separation equipment is that food waste is not cleaned up in time, and after entering the oil-water separation chamber, it ferments for a long time, which produces fatty acids and causes stench. Our company's oil-water separation and lifting equipment uses a pressurization screw conveying debris separator to thoroughly separate, classify, and collect solid debris in the front end of the equipment. It adopts a special two-stage secondary sludge separation and collection method to separate and classify the collection, ensuring that debris, food residue, etc., are thoroughly separated, thereby eliminating the source of stench from the root cause. Coupled with sealing and ventilation measures, a truly odorless, environmentally friendly, and reliable professional product is created.

How to discharge grease?

The "WGGY series fully automatic oil-water separation and lifting integrated equipment" completely subverts the shortcomings of the traditional oil-water separation equipment process design in its design concept. It adopts a two-stage separation new process for deep separation of oil and grease, and then uses the asymmetric conical collection structure above the oil-water separation area to collect the oil and grease. Considering that catering wastewater also contains a large number of detergents and other chemical substances, and the oil and grease are very easy to solidify into a scum-like state, the liquid level difference method cannot automatically discharge the oil and grease. Therefore, a chain automatic scraping and discharging oil device is adopted, and the large variability of Chinese food drainage flow is fully considered to safely and efficiently collect and discharge the oil and grease into a dedicated sealed oil drum for regular centralized transportation. Manual oil skimming is no longer needed, resulting in low operating costs and high efficiency. An electric heating device is set up, which is helpful for oil-water separation and facilitates manual oil discharge. The oil discharge is automatic and manual, truly realizing the fully automatic function of the equipment.

What is two-stage oil-water separation?

Two-stage oil-water separation uses two oil-water separation tanks to perform secondary separate oil-water separation treatment of catering wastewater. The two oil-water separation tanks operate in series to ensure the effectiveness of oil-water separation. The two-stage oil-water separation treatment process is mainly aimed at high-flow catering wastewater treatment with a processing capacity of 35m³/h or more. The two-stage oil-water separation treatment process can ensure the hydraulic retention time and meet the requirements of laminar flow Reynolds number, while ensuring the effectiveness of oil-water separation and solid-liquid separation. It operates stably with superior performance and excellent results.

How does the control system work?

The intelligent management and control system of the "WGGY series fully automatic oil-water separation and lifting integrated equipment" adopts CPU single-chip microcomputer control with Chinese display of the operating status. Its biggest highlight is process linkage control: that is, according to the processing requirements, it automatically starts the desludging machine, oil discharge device, heating device, and drainage device when there is a processing need, avoiding waste of power resources. The system uses a highly sensitive magnetic liquid level detection device and has functions such as multi-point monitoring, automatic alarm, overload and short-circuit protection, signal remote transmission (BA interface), and water pump water shortage protection.

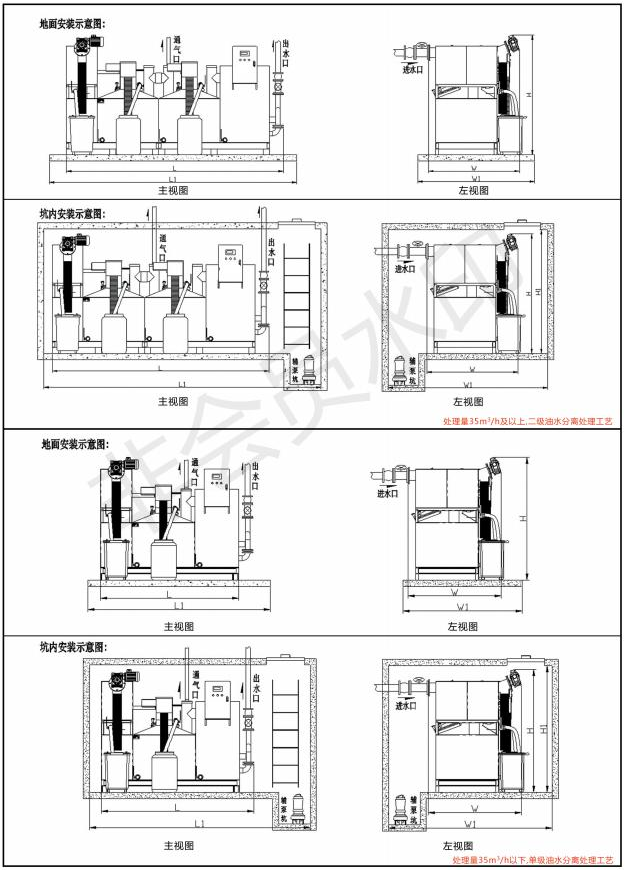

Equipment dimensions and installation diagram

Equipment dimensions and installation dimensions table

| Serial Number | Equipment Model | Flow (m³/h) | Head (m) | Inlet (DN) | Outlet (DN) | Total Power (kW) | Equipment Dimensions L×W×H (mm) | Installation Dimensions L1×W1×H1 (mm) |

|---|---|---|---|---|---|---|---|---|

| 1 | WGGY-10-15-1.5/2 | 10 | 15 | 10-15 | 65 | 5.5 | 2130×1480×2000 | 2930×2300×2500 |

| 2 | WGGY-10-20-1.5/2 | 10 | 20 | 15-20 | 65 | 5.5 | 2130×1480×2000 | 2930×2300×2500 |

| 3 | WGGY-10-25-2.2/2 | 10 | 25 | 20-25 | 65 | 6.9 | ||

| 4 | WGGY-15-15-1.5/2 | 15 | 15 | 10-15 | 65 | 5.5 | ||

| 5 | WGGY-15-20-2.2/2 | 15 | 20 | 15-20 | 100 | 6.5 | 2230×1480×2000 | 3030×2300×2500 |

| 6 | WGGY-15-25-3/2 | 15 | 25 | 20-25 | 65 | 8.5 | ||

| 7 | WGGY-20-15-1.5/2 | 20 | 15 | 10-15 | 65 | 5.5 | ||

| 8 | WGGY-20-20-2.2/2 | 20 | 20 | 15-20 | 65 | 6.9 | 2330×1480×2000 | 3130×2300×2500 |

| 9 | WGGY-20-25-3/2 | 20 | 25 | 20-25 | 65 | 8.5 | ||

| 10 | WGGY-25-15-1.5/2 | 25 | 15 | 10-15 | 65 | 5.5 | ||

| 11 | WGGY-25-20-2.2/2 | 25 | 20 | 15-20 | 150 | 6.9 | 2530×1480×2000 | 3330×2300×2500 |

| 12 | WGGY-25-25-3/2 | 25 | 25 | 20-25 | 65 | 8.5 | ||

| 13 | WGGY-30-15-2.2/2 | 30 | 15 | 10-15 | 65 | 5.5 | ||

| 14 | WGGY-30-20-3/2 | 30 | 20 | 15-20 | 150 | 6.9 | 2630×1520×2000 | 3430×2400×2500 |

| 15 | WGGY-30-25-4/2 | 30 | 25 | 20-25 | 65 | 8.5 | ||

| 16 | WGGY-35-15-2.2/2 | 35 | 15 | 10-15 | 65 | 10.5 | ||

| 17 | WGGY-35-20-3/2 | 35 | 20 | 15-20 | 150 | 12.5 | 3350×1480×2000 | 4150×2300×2500 |

| 18 | WGGY-35-25-4/2 | 35 | 25 | 20-25 | 65 | 10.5 | ||

| 19 | WGGY-40-15-3/2 | 40 | 15 | 10-15 | 65 | 12.5 | ||

| 20 | WGGY-40-20-4/2 | 40 | 20 | 15-20 | 150 | 12.5 | 3650×1480×2000 | 4450×2300×2500 |

| 21 | WGGY-40-25-4/2 | 40 | 25 | 20-28 | 65 | 12.5 | ||

| 22 | WGGY-50-15-4/2 | 50 | 15 | 10-15 | 65 | 12.5 | ||

| 23 | WGGY-50-20-4/2 | 50 | 20 | 15-20 | 150 | 12.5 | 4050×1480×2000 | 4850×2400×2500 |

| 24 | WGGY-50-25-5.5/2 | 50 | 25 | 20-28 | 65 | 15.5 |

Remarks:

■The above equipment dimensions do not include the dimensions of the tank, and the auxiliary pump pit and auxiliary pump are provided by the owner;

■If an external sewage pump is selected, L and L1 will be increased by 600mm accordingly;

■For flow rates of 35 (m²/h) and above, a double oil-water separation and split design is adopted;

■Customizable according to customer needs and on-site usage environment.

KEY WORD:WGGY series fully automatic oil-water separator and lifting integrated equipment

Related Products

Product Consultation

Leave your contact information to get a free product quote